Yield strength is a material property that indicates the amount of stress a material can withstand before it begins to deform plastically. The yield strength of a material is important for understanding its mechanical properties and predicting its behaviour in different applications. The yield strength is typically determined from a stress-strain curve, which shows the relationship between stress and strain for a given material.

In this blog, we will explore how to calculate yield strength from a stress-strain curve. We will start by defining some basic concepts related to stress and strain, followed by describing the stress-strain curve. Then, we will discuss identifying the yield point and calculating yield strength. Finally, we will conclude with some applications and limitations of yield strength calculations.

Stress and Strain

Stress is the force per unit area acting on a material. Stress is expressed in units of force per unit area, such as pounds per square inch (psi) or newtons per square meter (N/m²). Strain is the change in length or shape of a material under stress. Strain is expressed as a percentage or a decimal value.

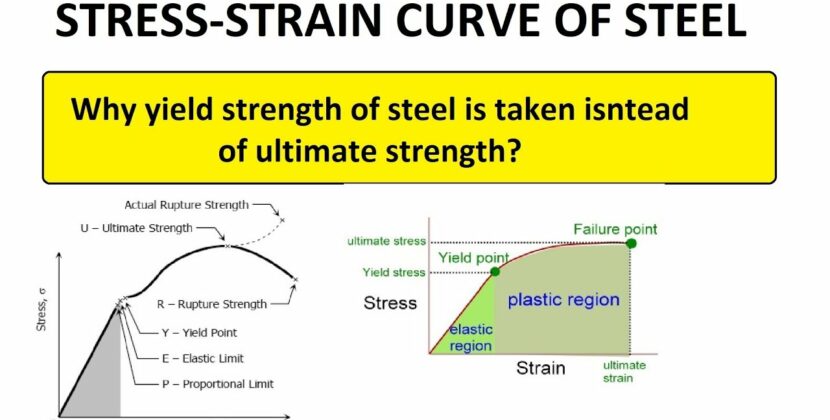

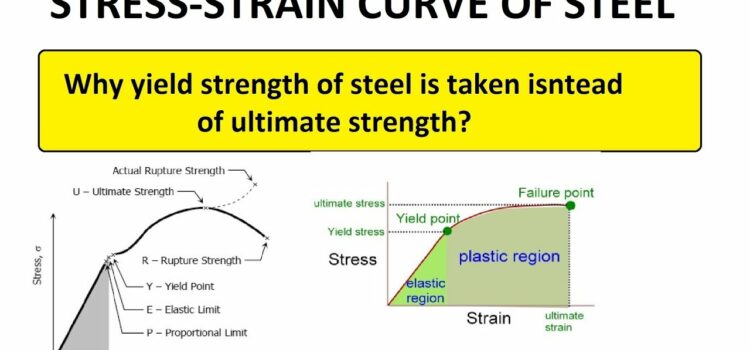

Stress-Strain Curve

A stress-strain curve is a graphical representation of the relationship between stress and strain for a given material. The curve shows how a material responds to stress as it is deformed.

Elastic Region

In the elastic region, the material behaves elastically, meaning it returns to its original shape when the stress is removed. The stress-strain relationship in this region is linear, and the slope of the curve is called the modulus of elasticity or Young’s modulus. The modulus of elasticity is a measure of the stiffness of the material.

Plastic Region

The material behaves plastically in the plastic region, which means it deforms permanently when stress is applied. The stress-strain relationship in this region is nonlinear, and the slope of the curve decreases as the material deforms.

Yield Point

The yield point is on the stress-strain curve, where the material begins to deform plastically. It is the point where the stress-strain relationship ceases to be linear and begins to curve. The yield point is an important parameter because it indicates the maximum stress that a material can withstand before it starts to deform plastically.

Calculating Yield Strength

The yield strength is the stress at which the material begins to deform plastically. Several methods for calculating yield strength from a stress-strain curve, including the offset and tangent methods. In this blog, we will focus on the offset method.

Offset Method

The offset is typically chosen to be 0.2% or 0.1% of the gauge length of the sample. The gauge length is the length of the sample over which the strain is measured. The stress at which the offset line intersects the stress-strain curve is taken as the yield strength.

Conclusion

The yield strength of a material is an important parameter that indicates the amount of stress a material can withstand before it begins to deform plastically. The yield strength is typically determined from a stress-strain curve, which shows the relationship between stress and strain for a given material. The offset method is a widely used for calculating yield strength from a stress-strain curve.